The Boldwater Bio-Technology

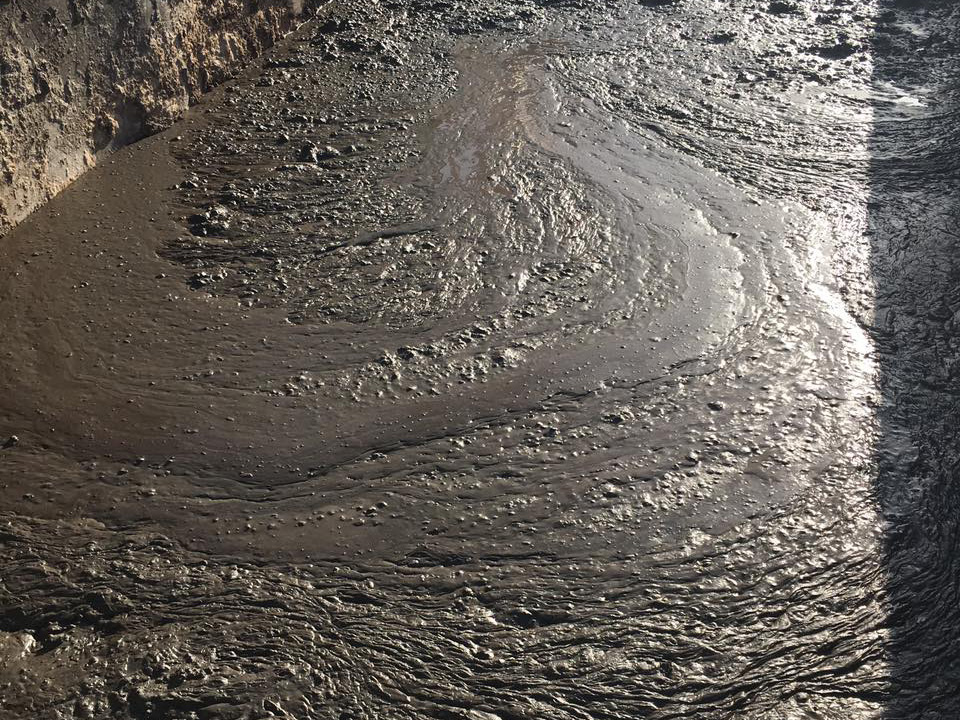

Boldwater has developed proprietary, patent-pending processes to Bio-Remediate and recycle hydrocarbon-contaminated soils generated in drilling and other industrial operations.

The first stage in the Boldwater Bio-Remediation process employs specially selected microorganisms to break down hydrocarbons in a process producing no harmful or environmentally unfriendly byproducts. The process is optimized to maximize microorganism activity and contact with hydrocarbons. As a result, hydrocarbon levels are rapidly reduced to below regulatory limits.

After Bio-Remediation, the material can be processed into a valuable road base, completing the Bio-Remediate-recycle process. This second process stage is critical because it severs the ongoing environmental and financial liability associated with solid oil and gas waste as recognized by the EPA. The Boldwater recycled base material can include both oil and water based drilling waste materials which exceed the Texas Department of Transportation specification for Grade 2 Flexible Base Material.

Each Bio-Remediation objective requires a thorough characterization of the material and conditions impacting the Work Plan. Project Work Plans are tailored to each situation taking into account factors such as the hydrocarbon contamination, volume to be treated, ambient conditions and time allowed on site. The equipment required to complete the process onsite easily integrates with existing operations including drying shakers configuration or the use of a cuttings dryer and centrifuge equipment.

Bio-Remediation is fully supported by regulatory authorities such as the Texas Railroad Commission (RRC) and the Environmental Protection Agency (EPA). In most states, regulatory agencies are advocating “reduce, recycle, reuse”. The Boldwater processes align with this effort, transforming waste into valuable reusable material while eliminating the need for traditional oil and gas waste disposal facilities.

The Boldwater Difference

The unique Boldwater process addresses the pitfalls associated with many remediation alternatives including:

“Relying on naturally occurring microbes”… beneficial microbes are not universal in the environment making burying waste an ineffective process. Such processes do not ensure contact between microbes and hydrocarbons and do not provide sufficient oxygen for decomposition to occur.

The Boldwater process maximizes microbial contact with contaminated particles in an environment designed for optimal hydrocarbon neutralization. Pre-release testing insures hydrocarbon levels are below regulatory limits before releasing the waste for recycling.

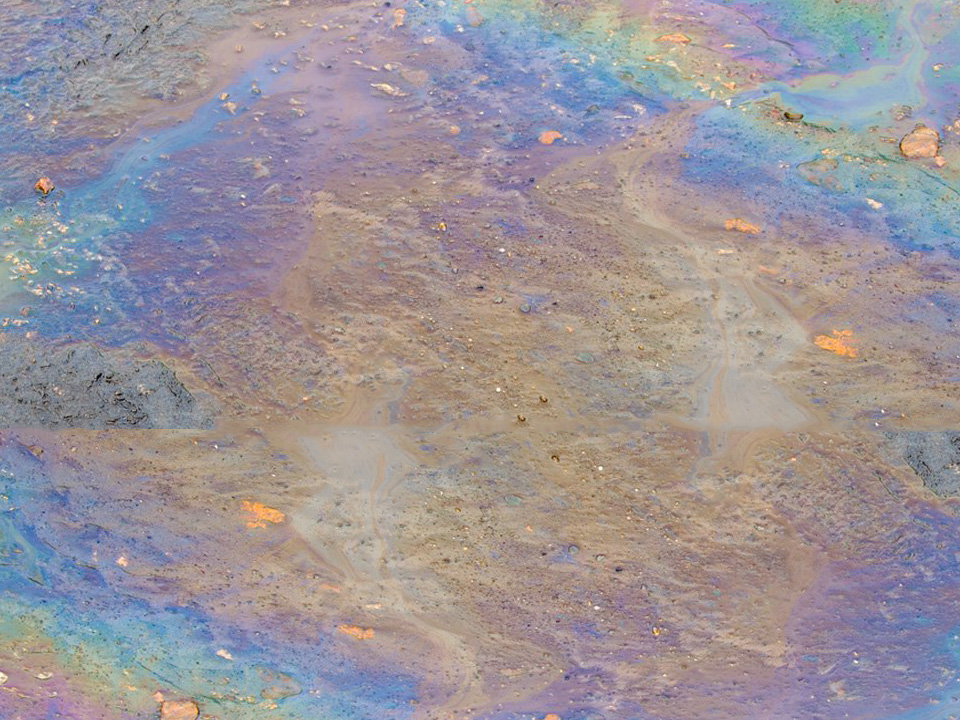

“Using surfactants and bio-solvents”… use of chemicals can separate the hydrocarbon from the waste material but only washes it into the soil and accelerates leaching toward ground water supplies. Hydrocarbons have been documented to move 300 feet in just the first year after entering the soil.

The Boldwater process breaks down the hydrocarbons into CO and H2O so that there is no contamination that can leach into the soil.

“On lease burial or road use”… Burying wastes or spreading on existing lease roads, even after relying on naturally occurring microbes or surfactants, carries ongoing environmental and financial liabilities for the operator and the landowner.

These permitted processes remediate and recycle contaminated soils and sever the chain of perpetual liability for both the operator and the landowner.

“Using waste disposal sites”… regulatory agencies have limited or denied new facility permits and current capacity is constrained. Offsite disposal also requires the expense and liability of trucking material in addition to costly disposal fees that is then managed by the waste facility on your behalf but all risks and Liabilities remain with you, the Operator.

The Boldwater process eliminates the need for waste disposal sites and the associated transportation costs and logistics while providing the operator with high quality flexible base material which is pre-approved for construction or maintaining lease, drilling or production pads, compressor or pump stations, and county roads.

The Boldwater Difference

- Regulatory permitted processes

- Lab confirmed and documented results for 14 control parameters and strength

- Hydrocarbon reduction well below regulatory limits

- Hazardous aromatics reduced to non-detectable levels

- Eliminates use of waste disposal sites

- Eliminates trucking and disposal costs

- and eliminates environmental risks and liabilities